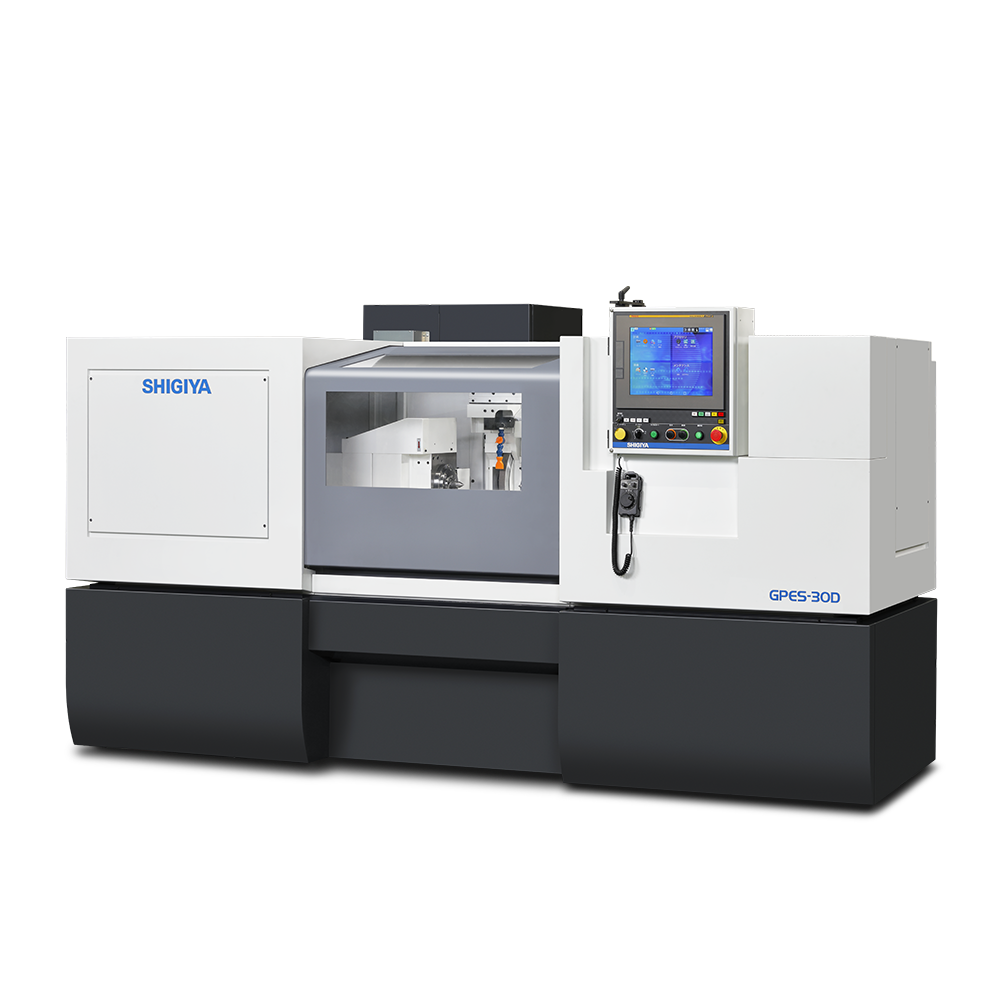

GPES-30D

Features

The highest level of grinding technology in pursuit of roundness and shape accuracy.

CNC Eccentric Pin/Polygon Grinder for high-precision, high-efficiency grinding of polygon shapes, punches used for eccentric pins of crankshafts, reduction gears for compressors, dies and tools, etc. This is achived by means of simple operations. Tapered traverse grinding and contour grinding is possible by superimposed control functions, which enables smooth jointing of non-circular shape R and straight lines.

Taking the full model change as an opportunity, our previous model was limited to only a hydro-static slide way. We now have capability of selecting from either: hydraulic static pressure (S type) or high-precision linear guide (L type) for the wheel slide way (x axis). By incorporating the visualization of the maintenance sensing technology, the correspondence option to IoT became possible.

Specifications

| GPES-30D | ||

|---|---|---|

| Swing over table | mm | φ300 |

| Distance between centers | mm | 300 / 600 |

| Max. grinding diameter | mm | φ300 |

| Load mass between centers | ㎏ | 30 |

| Wheel size O.D. × W × I.D. | mm | φ350 × 50 × φ127 |

| Wheel peripheral speed | m/s | 45 |

- Cylindrical Grinders [Plain and Angular]

- Universal Grinders

- Specialized Grinders

- Face Grinders

- Centerless Cylindrical Grinders